Problem Part Solutions

Y-Connector

ReproMed Systems is a manufacturer of infusion pumps for medication. Their pump is unique in that it operates at constant pressure as opposed to pumps which operate at constant volume. Through empirical experiments, ReproMed systems developed a guide for customers to determine pumping time for a given medication with a specific viscosity used with a given line set to the patient. To simply matters and provide a more efficient and accurate delivery of medication, ReproMed decided to produce their own needles and line sets to complement sales of their pumps.

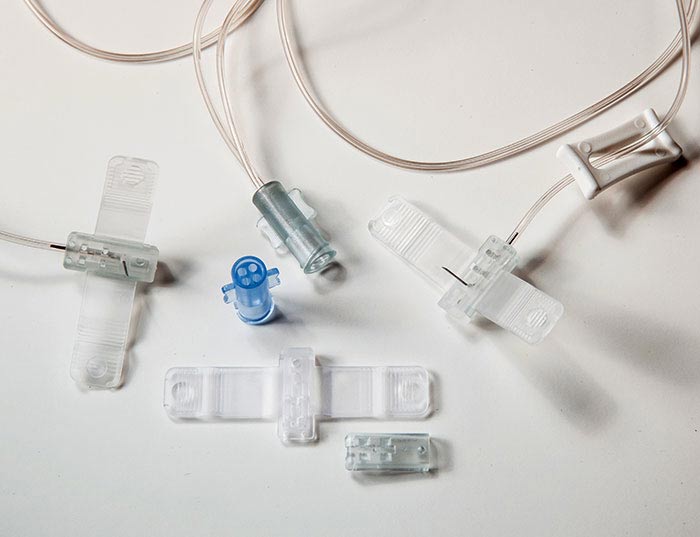

In researching the advantages and disadvantages of different line sets currently on the market, ReproMed determined there is a market for a ‘low residual’ connector to split line sets. The ‘low residual’ refers to the dead space inside the connector that contains medication at the end of treatment that is discarded with the line set. Because some of the medications used with ReproMed pumps are extremely expensive by weight/volume, the dead space or residual becomes an important characteristic of line sets. Unimpressed by connectors currently in use, ReproMed chose Tri-Tech to develop their own Y-Connector minimizing the residual for their own line set.

Molding connectors with small flow paths becomes a challenge because the steel that forms the flow channels in the mold becomes very small and can become flimsy. In addition, the luer type taper seals in these connectors have to be very precise or these components will leak. Tri-Tech was able to design tooling using only .040″ diameter cores at very aggressive L/D ratios to provide a part with minimal flow volume. We designed the mold without parting lines on the sealing surfaces and jig ground luer tapers to ensure an exact, no leak, fit. Tri-Tech also developed a mating retention nut which snapped on to the connector and threaded to standard luer locking threads. The retention nut was designed with strip type threads to allow for low cost tooling.

The Y-Connector assembly is now in regular production at Tri-Tech. In addition to being used with line sets from ReproMed, because of the luer sizes and threads used, it mates with standard commercially available connectors as well and helps fill out the product line available from ReproMed systems.

For more information or details on how Tri-Tech Tool can develop a plastic mold making solution for you, call Bill Weber now at 732-469-5433 or contact us online.